The engine body is the core support structure of the diesel engine. It serves as the mounting base for the crankshaft–connecting rod mechanism, valve train, and other major systems. The DEUTZ FL413F/513 engine body group mainly consists of the following components:

-

Cylinder block (engine block/crankcase)

-

Cylinder head

-

Cylinder gasket

-

Cylinder liner

-

Oil pan

1. Structure of the Engine Body

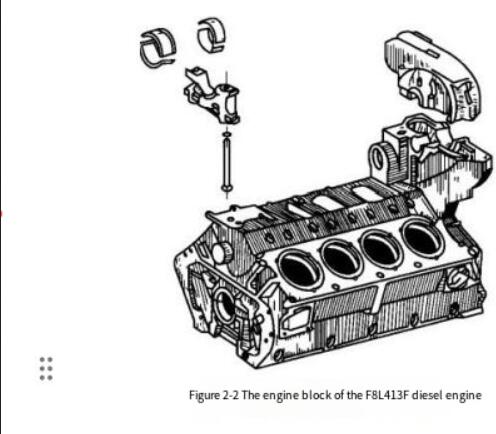

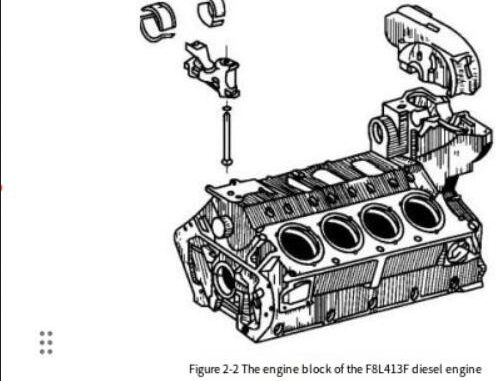

The FL413F/513 diesel engine adopts a gantry-type structure (see Figure 2-2), providing high rigidity.

-

The upper section of the V-shaped body features two cylinder liner mounting planes, angled at 90° to each other.

-

The middle section houses the injection pump bracket and fan transmission box.

-

The lower section forms the oil pan joint surface, set at a 45° angle to the cylinder liner mounting plane.

The body is cast from gray alloy cast iron (hardness 180–250HB).

Key dimensions:

-

Cylinder liner mounting hole distance: 165 mm

-

Cylinder liner hole diameter: 139 mm

-

Left and right liner mounting holes offset: 29 mm (due to the parallel connecting rod design).

Additional details:

-

Crankcase main bearing bottom hole: φ101 (+0.022) mm, with the third partition used for thrust positioning.

-

Main bearing caps are fixed using two M16×1.5 vertical bolts plus two M10 horizontal bolts. Material: QT50-5 ductile iron.

-

A φ22.5 mm main oil channel is cast into the crankcase, connected via a φ22 mm oil pipe to the main bearing hole.

2. Characteristics of the Engine Body

The FL413F/513 engine body has several notable features:

-

High standardization and interchangeability – Except for length, structures across different cylinder models are almost identical.

-

Compact design – The oil pan joint surface width is only 265 mm, allowing easy installation.

-

Increased rigidity – The transmission gearbox and crankcase are cast as one unit, strengthening the rear end.

-

Improved fastening – In addition to vertical bolts, the main bearing cover uses horizontal bolts, enhancing rigidity and reducing noise.

3. Common Damage Modes

The main types of damage that can occur include:

-

Breakage of connecting rod bolts.

-

Deformation, loss of roundness, or misalignment of the main bearing bottom hole (often caused by bearing failure).

-

Cracks or deformation in the cross partitions of the main bearing bottom hole (caused by overload or mechanical stress).

-

Other abnormal failures due to operational issues.

4. Inspection Points During Overhaul

Since the engine body is the foundation of the diesel engine, its condition directly affects performance and reliability. During overhaul, carefully inspect:

-

Main bearing bottom hole quality – Check for cracks, wear, out-of-round holes, or loss of coaxiality.

-

Water jacket and cross partitions – Look for cracks or looseness.

-

Mounting surfaces (cylinder liner and head) – Ensure they are flat, without deformation, pitting, or corrosion.

-

Oil channels – Verify that all lubrication and fuel channels are intact and unobstructed.

The engine body can only be reused if no defects are found. Otherwise, repairs must be performed before reassembly.

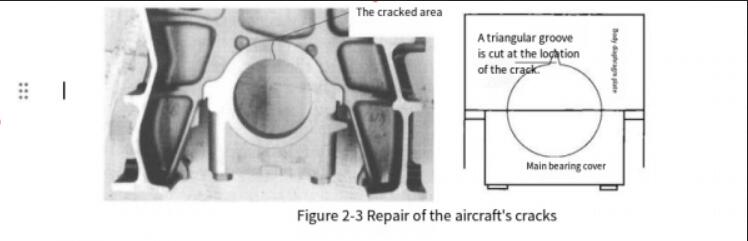

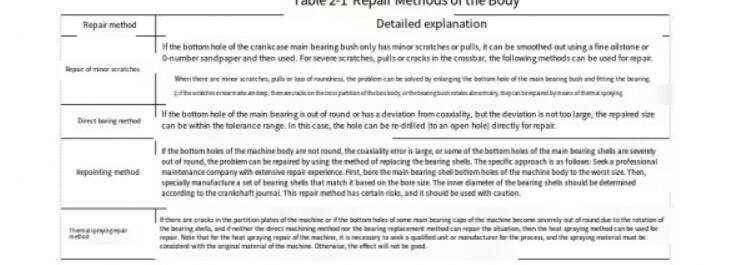

5. Repair of Cross-Plate Cracks

Failures caused by oil starvation (bearing seizure or wear) may result in deformation, out-of-roundness, or cracks in the main bearing bottom hole.

Repair methods:

-

The most effective method is thermal spraying, which restores the hole to its original dimensions and accuracy.

-

This technique has been successfully applied to F12L513 engine blocks, which have operated reliably for years after repair.

Note: Insufficient repair quality will prevent the engine from operating normally. Problems such as “cylinder pulling” are common in poorly repaired engines, so extra caution must be taken during inspection and repair.

More repair cases for Deutz Diesel engines,please refer to: Deutz Diesel Engine Repair