This guide explains the step-by-step procedure for installing the reverser drive on a CLAAS LEXION 480 combine harvester.

Related Contents:

CLAAS CDS 7.5 Diagnostic Software 2021 2020 Free Download

CLAAS Truck Diagnostic Tool agricultural machinery Claas Diagnostic Kit (CANUSB) Metadiag Diagnostic System CDS V7.51

CLAAS WEBTIC OFFLINE ENGLISH 2025.03 contains repair and service information

Components of the Disassembled Reverser Drive

- Hydraulic motor

- Hex. bolt M12 x 35 DIN 933-8.8

- Hex. nut M12 DIN 934-8

- Contact washer A12

- Supporting arm

- Bushing

- Washer

- Gearwheel

- Washer

- Hex. bolt M8 x 25 DIN 933-8.8

- Contact washer A8

- Hydraulic cylinder

- Hex. bolt M8 x 65 DIN 931-8.8

- Hex. nut M8 DIN 934

- Contact washer A8

- Hex. bolt M12 x 25 DIN 933-8.8

- Contact washer A12

- Eccentric

- Hex. bolt M12 x 45 DIN 931-8.8

- Contact washer A12

- Compression spring

- Hex. bolt M8 x 180 DIN 931-8.8

- Spring guide

- Hex. nut M8 DIN 934-8

- Bearing plate

- Hex. bolt M10 x 20 DIN 933-8.8

- Contact washer A10

- Set collar

- Set screw M10 x 8

- Mounting bracket

Installation Procedure

- Bolt the hydraulic motor (1) to the supporting arm (2).

- Fit the gearwheel (3) onto the shaft end of the hydraulic motor, using the washer, contact washer, and bolt.

- Attach the hydraulic cylinder (4) to the supporting arm (2).

- Slide the complete supporting arm (2) with bushings and washers onto the mounting bracket (9).

- Bolt the eccentric (5) to the hydraulic cylinder (4) and adjust so there is slight play.

- Install the compression spring (6). Tighten the nut until the end of the bolt thread.

- Bolt down the bearing plate (7), slide on the set collar (8), and tighten securely.

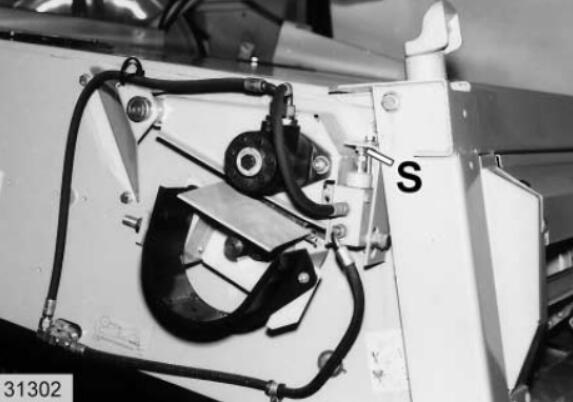

Adjusting the Hydraulic Cylinder

- Press the drive motor down into the gear.

- Pull out the ram.

- Adjust and lock the setting screw (S) so there is 0.5 mm of play (about 1/4 turn) up to the stop.

Final Steps

- Connect the hydraulic hoses to both the motor and hydraulic cylinder.

- Check the hydraulic oil level to ensure proper operation.

More repair case for CLAAS,please refer to CLAAS Trouble Repair