The Porsche PIWIS Tester 3 stands at the forefront of modern diagnostics, offering a comprehensive suite of features that have transformed how technicians service and repair Porsche vehicles. Combining powerful hardware with intuitive software. In this article, we take a look at how technicians are using PIWIS Tester III in real-world scenarios to boost diagnostic accuracy, streamline workflow, and deliver exceptional service.

Porsche Piwis 3 Tester III V43.300.22 + V38.250 Diagnostic tool with Engineering PIWIS 3 Software

Streamlined Diagnostics with High-Performance Hardware

One of the key advantages of the PIWIS Tester III is its ability to drastically reduce diagnostic time. Equipped with an Intel Core i5 processor and 8 GB of RAM, the PT3 delivers fast and responsive performance. This is especially critical in high-traffic service environments, where every minute saved enhances productivity.

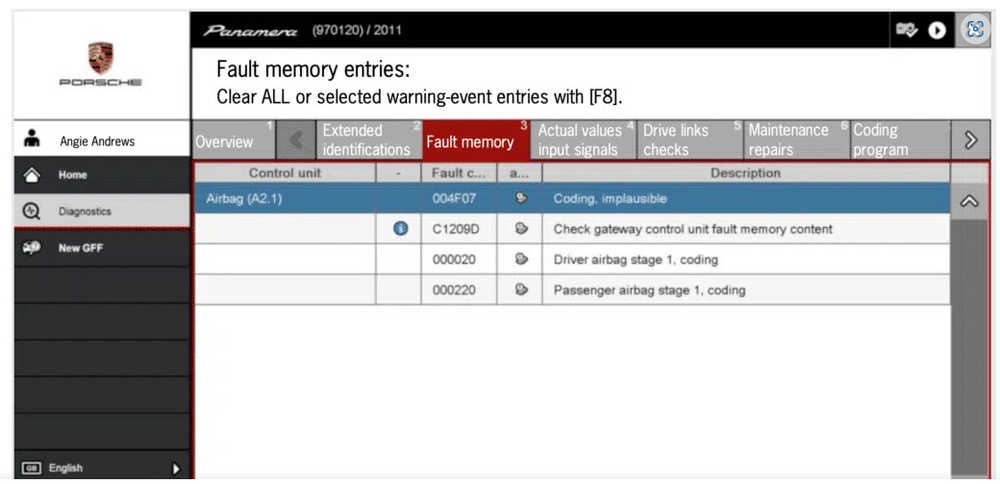

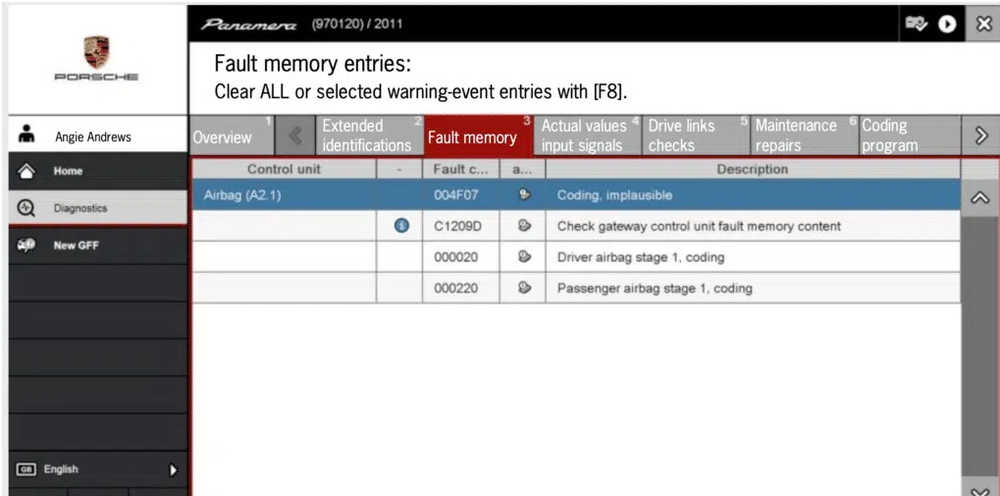

Guided Fault Finding (GFF): Precision with Every Step

The Guided Fault Finding (GFF) function sets the PIWIS Tester III apart. It links directly to essential technical resources like wiring diagrams, system measurements, and detailed diagnostic data. GFF walks technicians through the troubleshooting process, enabling accurate fault detection and repair — reducing guesswork and minimizing repeat visits.

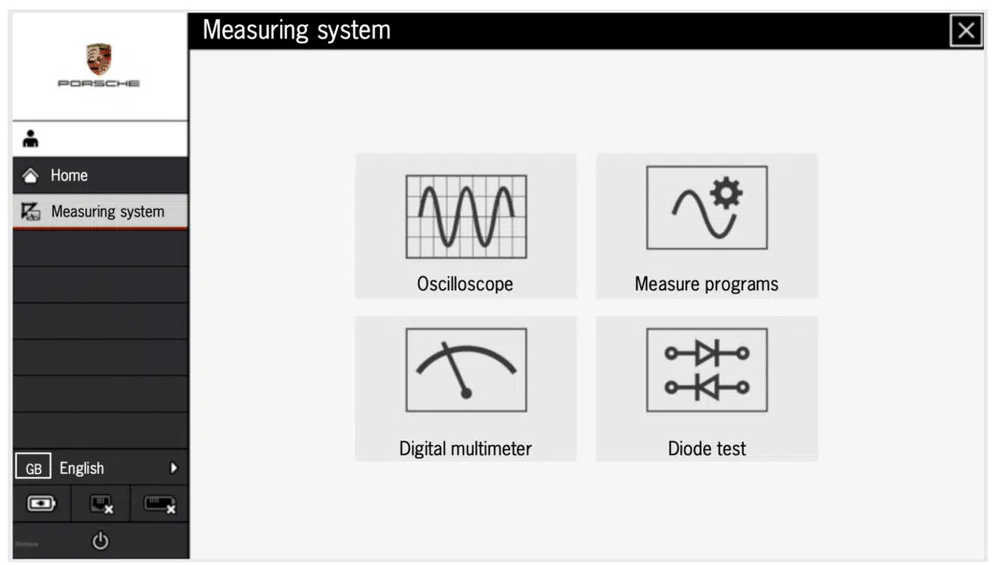

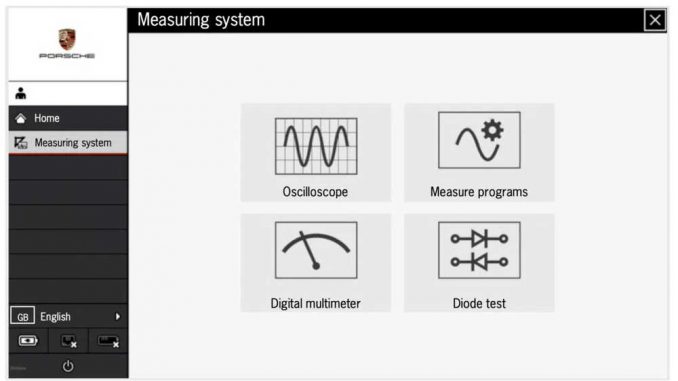

Advanced Measuring System

PIWIS Tester 3 includes an integrated measuring system that supports electrical diagnostics across 12V to 24V systems. Its built-in 4-channel oscilloscope and digital multimeter allow for advanced testing of:

Voltage and current

Resistance and continuity

Diode functionality

These features empower technicians to perform deep diagnostics on complex systems with confidence.

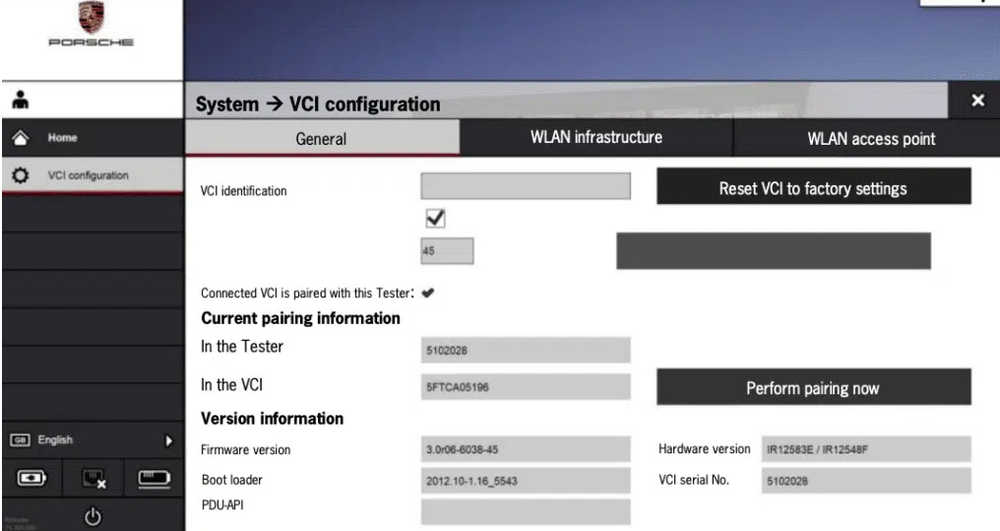

Seamless VCI Configuration

The Vehicle Communication Interface (VCI) ensures stable, reliable connectivity between the tool and the vehicle. Whether via WLAN or direct cable, VCI setup is straightforward and essential for accurate, real-time data exchange. This connectivity flexibility allows technicians to move efficiently between bays without sacrificing diagnostic performance.

Automatic Coding and Diagnostic Logging

The PIWIS Tester III streamlines vehicle setup with its automatic coding function, which resets control modules to their default state while retaining critical customer-specific settings. The built-in logging feature lets technicians capture screenshots and generate log files during the diagnostic process — a valuable asset for documentation, analysis, and team collaboration.

Real-World Applications

1. Routine Maintenance

The PT3 excels in preventative diagnostics, allowing technicians to uncover hidden issues during routine service. By identifying potential problems early, the tool helps reduce long-term costs and prevent breakdowns.

2. Complex Diagnostics and Repairs

In more advanced repair scenarios, the PIWIS Tester III’s GFF and measuring capabilities provide the depth and precision needed to address complex faults. This leads to more accurate repairs and fewer comebacks.

3. Pre-Owned Vehicle Evaluations

When assessing used Porsche vehicles, the PT3 gives technicians a full diagnostic snapshot. It highlights any underlying issues, helping buyers and sellers make informed decisions based on system performance and fault history.

Conclusion

The PIWIS Tester III is more than just a diagnostic tool — it’s a comprehensive service solution for modern Porsche technicians. Its blend of powerful hardware, smart diagnostics, and user-friendly features makes it a must-have in any Porsche service center.

From everyday maintenance to in-depth troubleshooting, the PT3 equips technicians with the tools they need to deliver precision service, enhance customer satisfaction, and maintain Porsche’s high-performance standards.