Here’s a step-by-step guide for replacing the engine rotation speed sensor (crankshaft speed sensor) on a Volvo EC500F L5:

Related Contents:

Volvo VOCOM 88890300 Diagnostic Kit

Volvo EC500F L5 Engine Rotation Speed Sensor Crankshaft Replacement Guide

Tools and Materials Needed:

- 88800031 Setting Tool

- New crankshaft speed sensor

- New O-ring

- Engine oil (for O-ring lubrication)

Procedures:

- Prepare the Machine:

- Position the machine in location A for safe and accessible operations.

- Safety First:

- Turn OFF the battery disconnect switch to ensure there is no power running through the machine while you work.

- Access the Sensor:

- Remove the pump room covers to gain access to the crankshaft speed sensor.

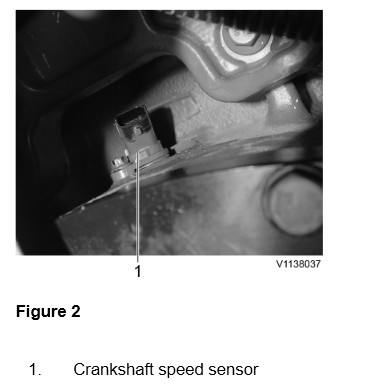

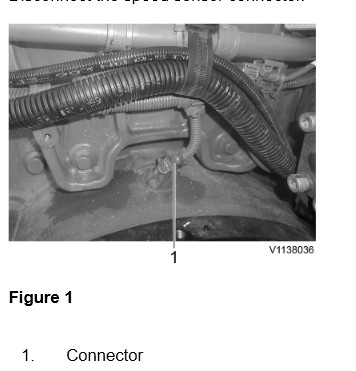

- Disconnect the Sensor:

- Remove the Old Sensor:

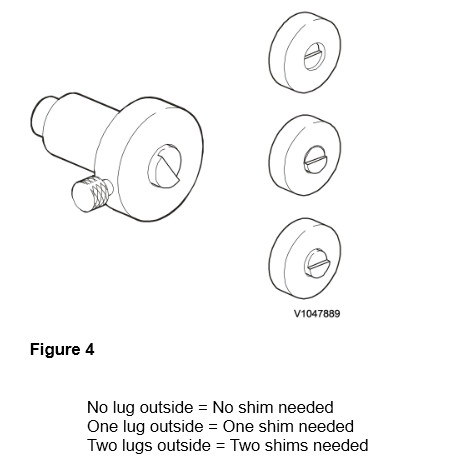

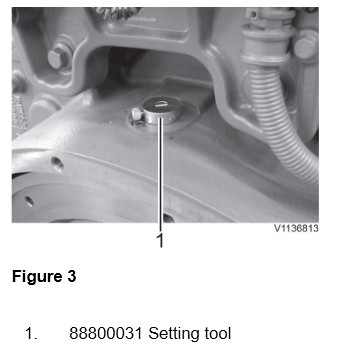

- Set the Correct Shim Thickness:

- Use the 88800031 Setting Tool to measure and determine the correct shim thickness needed for the new sensor. This ensures proper clearance and alignment with the flywheel.

- Install the setting tool and tighten the lock screw.

- Remove the tool and verify the distance to the flywheel’s tooth is correct.

- Install the New Sensor:

- Reconnect the Sensor:

- Reconnect the speed sensor connector ensuring it is secure and properly aligned.

- Reassemble the Machine:

- Reinstall the pump room covers, ensuring they are securely fastened.

- Test the Installation:

- Turn ON the battery disconnect switch.

- Start the machine and check the function of the new crankshaft speed sensor to ensure it is operating correctly.

Final Check:

After completing these steps, it’s important to monitor the sensor’s performance to ensure there are no issues with readings. If the sensor isn’t functioning as expected, recheck all connections and installation parameters. Additionally, consult the Volvo excavator’s troubleshooting guide for further insights into potential issues or error codes related to the crankshaft speed sensor.

More repair case for Volvo machine,please refer to Volvo excavator trouble repair