The GHG17 heavy duty machine is a powerful piece of equipment used in various industries. It is crucial to ensure that the fuel system of this machine is in optimal condition to ensure its efficient operation. One important test that needs to be conducted is the FIS (Fuel Injection System) low pressure leak test. In this article, we will guide you on how to perform this test using the DDDL (Detroit Diesel Diagnostic Link) diagnostic software.

Preparations:

Detroit Diesel Diagnostic Link DDDL 8

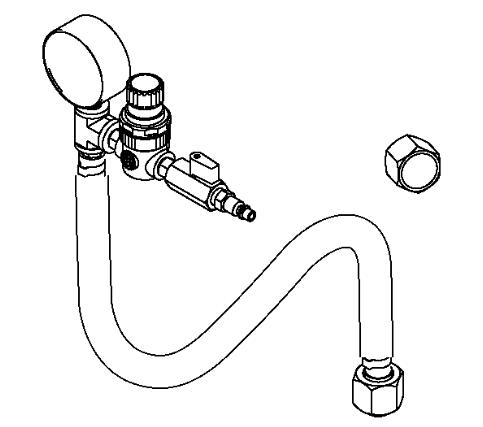

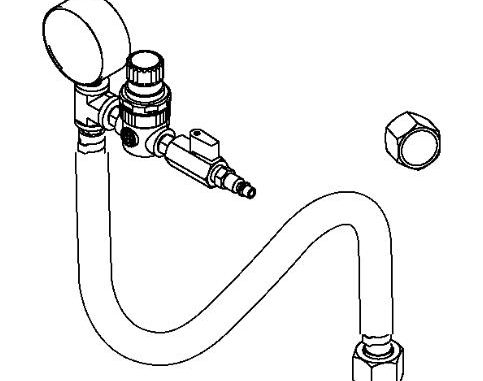

J48710 Air Pressure Test Kit Fuel system

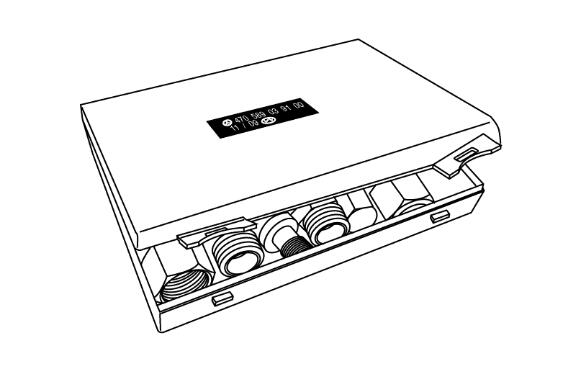

W470589039100 Fuel system tool update kit without an MCM cooler

Procedures:

Note:Please review 13 TL-11REV to ensure changes to essential tool J-48710 have been made to improve the accuracy of detecting low pressure fuel system leaks.

Test as follows:

1. With the engine OFF, apply the parking brake, chock the wheels and perform any other applicable safety steps.

2. Remove the fuel tank fill caps.

3. Remove the fuel feed line from the fuel filter module.

WARNING

Pressurized air and flying particles. To avoid injury to eye or face, wear a face shield or goggles when conducting a pressure test.

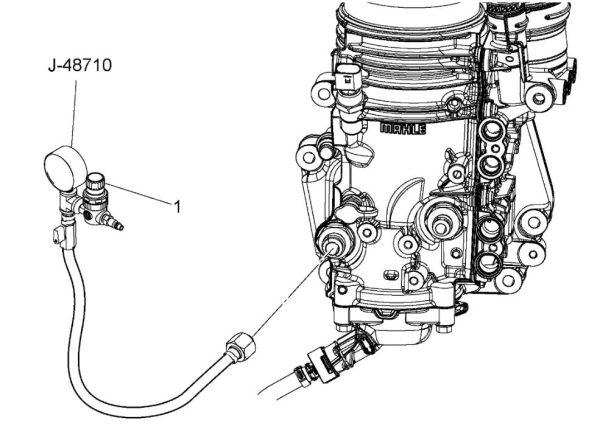

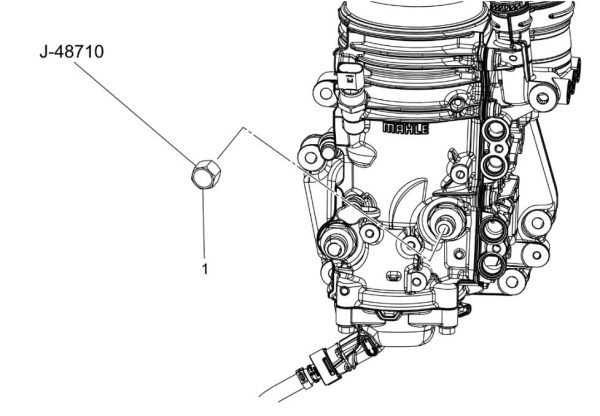

4. Install J-48710 tool (1) on to the fuel filter module.

5. Connect an air supply to J-48710 tool.

6. Pressurize the fuel system to 517 kPa (75 psi) for six minutes.

7. Close the ball valve on J-48710 tool.

8. Wait two minutes.

9. Remove the return line from the fuel filter module and install J-48710 cap tool (1) on the fuel filter module return line fitting.

10. Install the fuel tank fill caps.

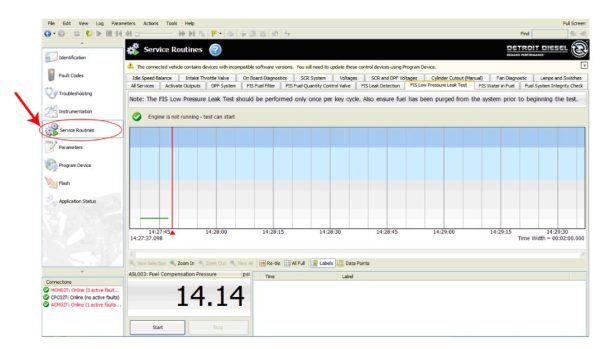

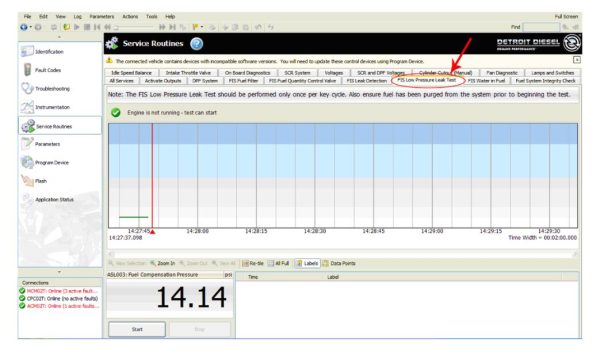

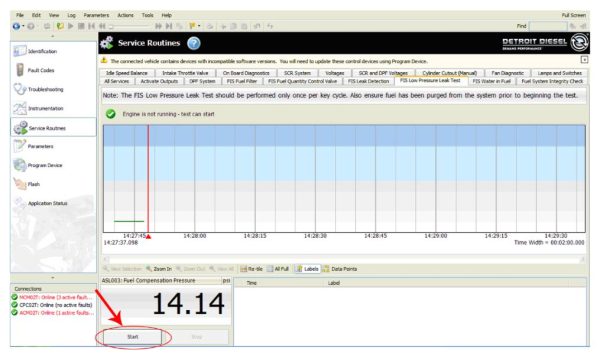

11. Ignition ON, engine OFF, connect to the MCM using DDDL 8.15 DiagnosticLink.

12. Click the “service routines” tab in DiagnosticLink.

13. Click the “FIS Low Pressure Leak Test” tab in DiagnosticLink.

WARNING

Pressurized air and flying particles. To avoid injury to eye or face, wear a face shield or goggles when conducting a pressure test.

14. Using J-48710 tool, pressurize the fuel system to 517 kPa (75 psi) for four minutes.

15. Close the ball valve and disconnect the air supply from J-48710 tool.

Note: The fuel compensation pressure will increase after the “Start” button has been pressed.

Note: The fuel compensation pressure sensor reads in absolute pressure, therefore the pressure should read about 100 kPa (14.5 psi) (depending on elevation) more than the fuel pressure gauge on the J 48710 tool. The fuel compensation sensor will read close to 620 kPa (90 psi) of pressure when the J 48710 tool is reading 517 kPa (75 psi).

16. Press the “Start” button on DiagnosticLink.

17. Once the test is complete, review the DiagnosticLink log file test results.

18. Did the fuel system pass the FIS Low Pressure Leak Test?

18.a Yes -> slowly remove the J-48710 cap tool from the fuel filter module. Remove the J-48710 tool from the fuel filter module. Install the fuel feed line and return line on to the fuel filter module. Return to the initial diagnostics that directed you to the FIS Low Pressure Leak Test.

18.b No -> Go to step 19.

WARNING

Pressurized air and flying particles. To avoid injury to eye or face, wear a face shield or goggles when conducting a pressure test.

19. Connect an air supply to the J-48710 tool.

20. Open the ball valve and pressurize the fuel system to 517 kPa (75 psi).

21. Locate leak by using a soapy solution, spray connectors, fittings and hoses shown in the “Potential Fuel Leak Points-Two-Filter Fuel System” procedure.