To be able to run a thorough diagnostic of an agricultural vehicle (AGV), it is integral for the repairer that they can understand the appropriate fault codes and which part they relate to, as this helps to conduct the correct repairs.

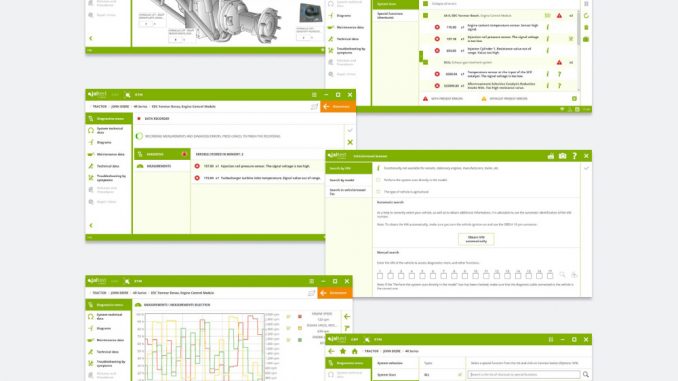

Repairs have gone beyond a couple of tools and a service manual, there are many complexities that make up the process. Which is why we recommend diagnostic tools such as Jaltest. With its wide coverage across various vehicle types and brands, Jaltest AGV is the complete workshop solution.

In this article, we will discuss why fault codes are important and share some of the most common AGV vehicle fault codes you should be aware of.

What are fault codes?

Fault codes, also known as diagnostic trouble codes (DTC), are fault codes that are stored in the vehicle’s ECU which correspond to a specific malfunction that has occurred. Technicians can see all the fault codes stored within the vehicle’s ECU by plugging a diagnostic tool into the onboard ports and then running a system scan, which looks at all the ECUs connected to the vehicle.

Unlike some other tools, Jaltest uses the same fault codes as the manufacturer of the vehicle, making the repairer’s life easier as they will have a universally understood code that can be obtained and provided to the dealer.

How do I read AGV fault codes?

The first number in the fault code will tell you if the error is a manufacturer-specific problem or if it is applicable to all systems. Then, the last three numbers will give you more information about the specific electrical circuit and system.

To get further information about what exactly has failed, Jaltest users have access to fault code descriptions, which give a brief description of what the fault is, and what system it relates to. These fault code descriptions are user-friendly making the process of diagnosing a fault much easier.

Common fault codes you should be aware of

Now that you have a better understanding of fault codes and how to read them, let’s investigate the common fault codes that can occur in agricultural vehicles across some of the most popular manufacturers including John Deere, Massey Ferguson, Fendt, and JCB.

🔴 CIS error code E-41

FAULT DESCRIPTION

* Ground drive variable displacement motor solenoid coil (Y144) defective.

* The cable connection is defective.

OPERATION CONDITION

Restricted operation:

* Solenoid coil Y144 cannot be energised.

* Driving at 7 km/h max. in 1st gear, approx. 12 km/h in 2nd gear.

REMEDY

* Check the cable connection to solenoid coil Y144.

* Measure resistance of solenoid coil Y144.

* Measured value: 6 – 12 Ω.

* Check the connector on solenoid coil Y144.

* In case of a hardware fault, replace the module.

🔴 Error code E-46

FAULT DESCRIPTION

* Ground speed control lever potentiometer (R39) defective.

OPERATION CONDITION

Emergency operation:

* The machine can be moved with a speed of approx. 1 km/h only in a forward direction (identification of the direction of travel by neutral switch Z57-2 and the reversing horn switch Z50).

* Check the supply voltage of the ground speed control lever position potentiometer (R39). Measured value: approx. 8.5 Volt.

* Check the wiring loom from the module to the potentiometer for interruptions or short-circuit. Signal 2 from the potentiometer is an opposite signal which, when added to signal 1 of the potentiometer, always must result in the same value.

Total measured value:

* 3 – 7.5 Volt.

Example 1:

* Signal 1 = 4.0 V

* Signal 2 = 3.4 V

* Addition: 4.0 + 3.4 = 7.4V = R39 potentiometer is OK.

Example 2:

* Signal 2 = 1.0 V

* Addition: 4.0 + 1.0 = 5.0V

* R39 potentiometer is defective. Replace the ground speed control lever position potentiometer (R39).

🔴 Fault code E-196 EFA

FAULT DESCRIPTION

* A49 No signal from ground drive hydraulics reverse high-pressure sensor (B98).

OPERATION CONDITION

Restricted operation:

* Driving at 7 km/h max. in 1st gear, approx.12 km/h in 2nd gear.

REMEDY

The ground drive hydraulics reverse high-pressure sensor (B98) does not transmit any signal:

* Check if the cable connection from the module to the pressure sensor is interrupted or if there is a short circuit.

* Check the pressure sensor connector.

* Replace the pressure sensor.

* Check cable 014 317.2 in the corrugated sheath leading to the pressure

🔴 Fault code E-199

FAULT DESCRIPTION

* A49 Ground speed control lever neutral – The safety start switch actual value switch (Z57-2) is not recognized.

OPERATION CONDITION

* A machine cannot be driven. Although, the ground speed control lever is moved.

REMEDY

* Check linkage, fixing and setting.

* Check switching signal of the ground speed control lever neutral – Safety start switch actual value switch (Z57- 2).

* Check the position of the shifter roll/tab (on the potentiometer) relative to the segment. The tab may be bent. In the neutral position of the ground speed control lever, signal 1 from the ground speed control lever position potentiometer (R39) is 3.8 – 3.9 V on the CIS terminal.

🔴 BRC 524016.04 – Front Brake Control Unit

FAULT DESCRIPTION

* The secondary braking system fault buzzer indicates – urgent.

POSSIBLE CAUSES

* Secondary brake system fault.

* Switched supply voltage problem – *9.5V.

REMEDY

* Check secondary handbrake solenoid wiring (wiring diagram available on Jaltest).

* Check and replace Fuse F24.

* Carry out solenoid actuation – if not movement, replace the solenoid.

🔴 SFA 524016.04 – Front Suspension System

FAULT DESCRIPTION

* SFA switched supply voltage low/front axle direction solenoid. Power steering is weak or has no effort, the alarm buzzer indicates urgent, and suspension is non-adjustable.

POSSIBLE CAUSES

* SFA Disabled

* Code caused by valve battery supply voltage less than 9.5 V.

REMEDY

* Check around the battery/alternator for debris or corrosion.

* Delete active fault codes.

* Start the vehicle and operate on rough terrain for 5 minutes – if the fault returns, check the wiring to the Vehicle Load Centre (VLC).

* Carry out alternator check – carry out the repair if needed.

🔴 T 6145 X15 – PTO Clutch Speed Sensor

FAULT DESCRIPTION

* X15 – PTO clutch speed sensor

POSSIBLE CAUSES

* NEUTRAL speed selection, PTO not activated, X15 displays a speed, the clutch disc does not separate, PTO brake does not engage selected speed, PTO clutch 100% engaged, over 20% difference between PTO clutch speed and engine speed.

* PTO clutch disc slips: clutch slippage.

* PTO clutch speed is lower than output shaft speed, X15 sensor supply voltage error

🔴 A/C Fault 24

FAULT DESCRIPTION

* Engine speed error

POSSIBLE CAUSES

* The CAN message is not valid.

* The system considers the last value received within 2 seconds.

* If no CAN message is received during this time, the system takes a default value of 1500 rpm.

🔴 Fault Code 1.2.07

FAULT DESCRIPTION

* B053 Sensor, charge air temperature/boost pressure (EMR)

* Boost pressure signal error. Signal out of range.

POSSIBLE CAUSES

* The A022 – ECU, EMR uses a substitute value to calculate the quantity injected or reduced output of the tractor.

REMEDY

* Check the sensor cable connection, replace the sensor

🔴 Fault Code 1.2.94

FAULT DESCRIPTION

* ECU EMR2 internal processing error in ECU EMR2

REMEDY

* Emergency shutoff, the engine does not start, switch ignition OFF then ON, if error reappears –> load new data record in ECU EMR2

IMPORTANT NOTE

* Save the old data record! If the error reappears –> replace ECU EMR2

🔴 Fault Code 4.1.41

FAULT DESCRIPTION

* Engine speed hall sensor 2. Signal fault.

OPERATION CONDITION

Continuation in emergency mode is possible.

REMEDY

* Check: 12 V supply fault; A013 fuse 2.

🔴 P3424

FAULT DESCRIPTION

* SCR catalyst status is very high

POSSIBLE CAUSES

* SCR running refresh was not successful.

REMEDY

Important: Stop the engine and let it cool before you start work. Do not start the engine during the service procedures (SN0001)

* Perform the exhaust after-treatment catalyst refresh procedure immediately. Refer to the machine operator’s manual.

RELATED FAULT CODES

* P3424-85 – SCR catalyst partially blocked (overloaded). Signal above allowable range.

Final thoughts

Overall, the article provides a top-level overview of the most common fault codes in agricultural vehicles. If you encounter any of these issues, the next natural step is to conduct a more detailed troubleshooting test, with Jaltest. By using it, you gain dealer-level access, which unlocks all the information needed to carry out the repairs in an efficient way.

All in all, fault codes are unavoidable in agricultural vehicles that are in heavy use. And especially nowadays, where there might be tens or hundreds of computers on-board your vehicle, software, like Jaltest, has become a must-have for interpreting and fixing these fault codes.

So, if you’re searching for an industry-leading diagnostics tool for your agricultural vehicle fleet, look no further – book a free demonstration with our team today!